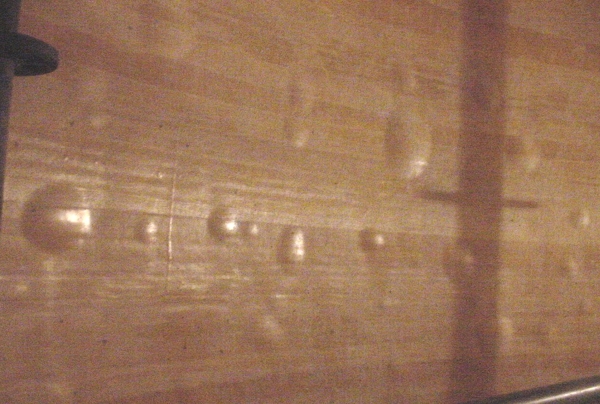

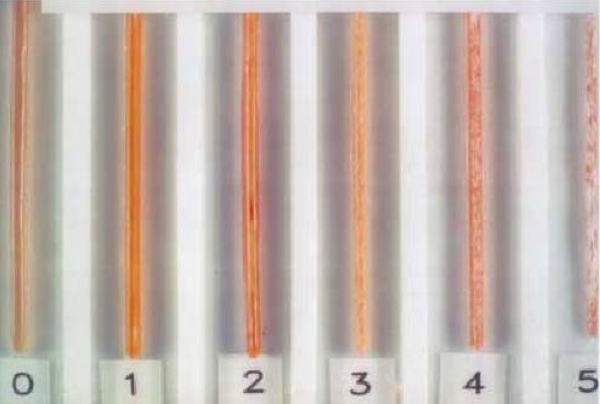

FIGURE S2.10.4.2 b)

CONTINUOUS BULGING WHERE ONLY SOME BULGES EXCEED ALLOWABLE DEFORMATION

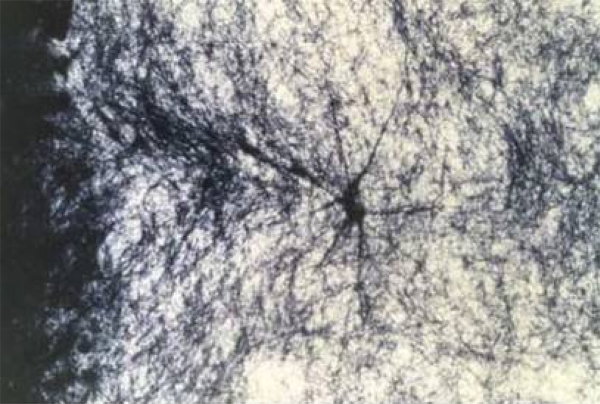

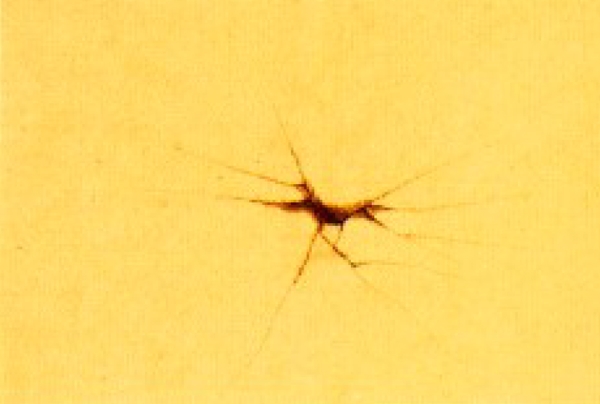

Figure S4.7.2

STAR CRACK IN CORRODED LINER. POSSIBLE CAUSE IS EXTERNAL IMPACT.

Figure S4.7.3-a

GUSSET CRACK. POSSIBLE CAUSES ARE EXCESSIVE LOAD DUE TO UNSUPPORTED VALVE, PIPE, OR OVERSTRESS AND AGE.

Figure S4.7.3-b

CRACKED FLANGE. POSSIBLE CAUSES ARE INCORRECT MATCH-UP OF FLANGES, OVER-TORQUE OF BOLTS AT FIT-UP, MANUFACTURING DEFECT, OR EXCESSIVE PIPING LOADS.

Figure S4.7.3-c

CRACKED FLANGE. POSSIBLE CAUSE IS BOLTING DISSIMILAR FLANGES TOGETHER (FULL-FACED FLANGE WITH RAISED-FACE FLANGE).

Figure S4.10-a

EXCESSIVE HEAT. POSSIBLE CAUSES ARE LOCALIZED HIGH-TEMPERATURE EXCURSIONS.

Figure S4.10-b

LAMINATE VOIDS AT OVERLAYS.

Figure S4.10-c

SURFACE DETERIORATIONS. POSSIBLE CAUSES ARE EXPOSURE TO HOT WATER AND/OR STEAM AND CHEMICAL ATTACK.

Figure S4.10-d

BLISTERS. POSSIBLE CAUSE IS EXPOSURE TO STEAM OR PURIFIED HOT WATER.

Figure S4.10-e

SURFACE EROSION. POSSIBLE CAUSES ARE HIGH FLOW RATE OF FLUIDS, EROSION DUE TO PARTICULATES IN FLUID, AND CHEMICAL ATTACK/SOFTENING OF RESIN.

Figure S4.10-f

CORROSION/EROSION.

Figure S4.10-g

CRACKS. POSSIBLE CAUSE IS IMPACT FROM AN EXTERNAL SOURCE.

Figure S4.10-h

CORROSION (LOSS OF VEIL).

Figure S4.10-i

SHELL FRACTURE. POSSIBLE CAUSE IS EXTERIOR IMPACT.

Figure S4.10-j

CONCENTRATED SULFURIC ACID ATTACK.

Figure S4.10-k

BLISTER.

Figure S4.10-l

FIBER PROMINENCE. POSSIBLE CAUSE IS EXPOSURE TO SUNLIGHT AND NO UV PROTECTION.

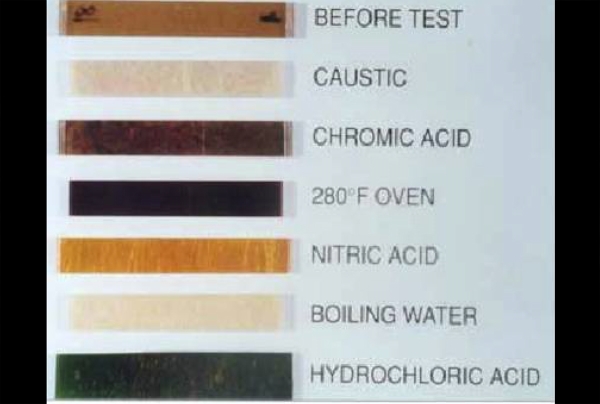

Figure S4.10-m

COLOR CHANGE.

Figure S4.10-n

CUT EDGE EVALUATION.

Figure S4.10-o

EROSION IN THE LINER.

Figure S4.10-p

GOUGE. POSSIBLE CAUSE IS MECHANICAL DAMAGE.

Figure S4.10-q

CRACKS AT THE KNUCKLE. POSSIBLE CAUSE IS INADEQUATE ANCHORING OF VESSEL.

Figure S4.10-r

SULFURIC ACID ATTACK AND THERMAL SHOCK.

Figure S4.10-s

AIR BUBBLES BEHIND THE VEIL (SHOWN AFTER CHEMICAL EXPOSURE)

Figure S4.10-t

DELAMINATIONS AND BLISTERS. POSSIBLE CAUSES ARE EXPOSURE TO HIGH HEAT OR IMPROPER SURFACE PREPARATION OF LINER PRIOR TO STRUCTURAL APPLICATION.

Figure S4.10-u

FLANGE CRACKING.

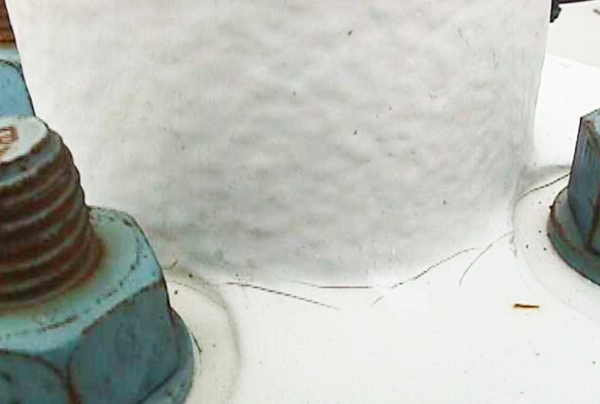

Figure S4.10-v

ELASTOMERIC GASKET EXTRUDING. POSSIBLE CAUSES ARE EXCESSIVE BOLT TORQUE OR IMPROPER BOLTING SEQUENCE.

Figure S4.10-w

INCORRECT GUSSET ATTACHMENT. POSSIBLE CAUSES ARE GUSSETS NOT EXTENDING OUT FROM FLANGE A MINIMUM OF 30° FROM THE AXIS OF NOZZLE NECK, OR GUSSET ATTACHMENTS USED AS PART OF THE FLANGE THICKNESS.

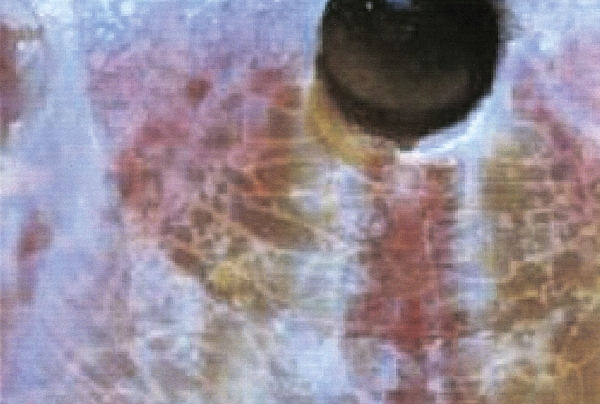

Figure S4.10-x

STAR CRACK. POSSIBLE CAUSE IS EXTERNAL IMPACT.

Figure S4.10-y

EXCESSIVE USE OF PUTTY.

FIGURE S10.10

ROLLING BALL IMPACT CALIBRATION SETUP

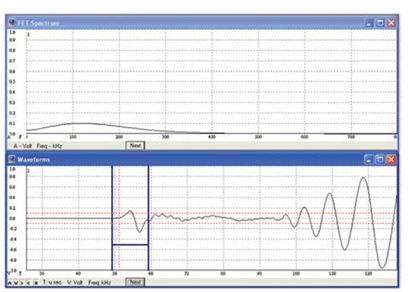

FIGURE S10.10.3

FRONT END WAVEFORM